Our Services

Our integrated team of designers, machinists,

and R&D engineers will lead you through product

conceptualization and prototyping to assembly.

-

MEDICAL DEVICE ASSEMBLY

Class 100 Clean Room for medical device assembly.

-

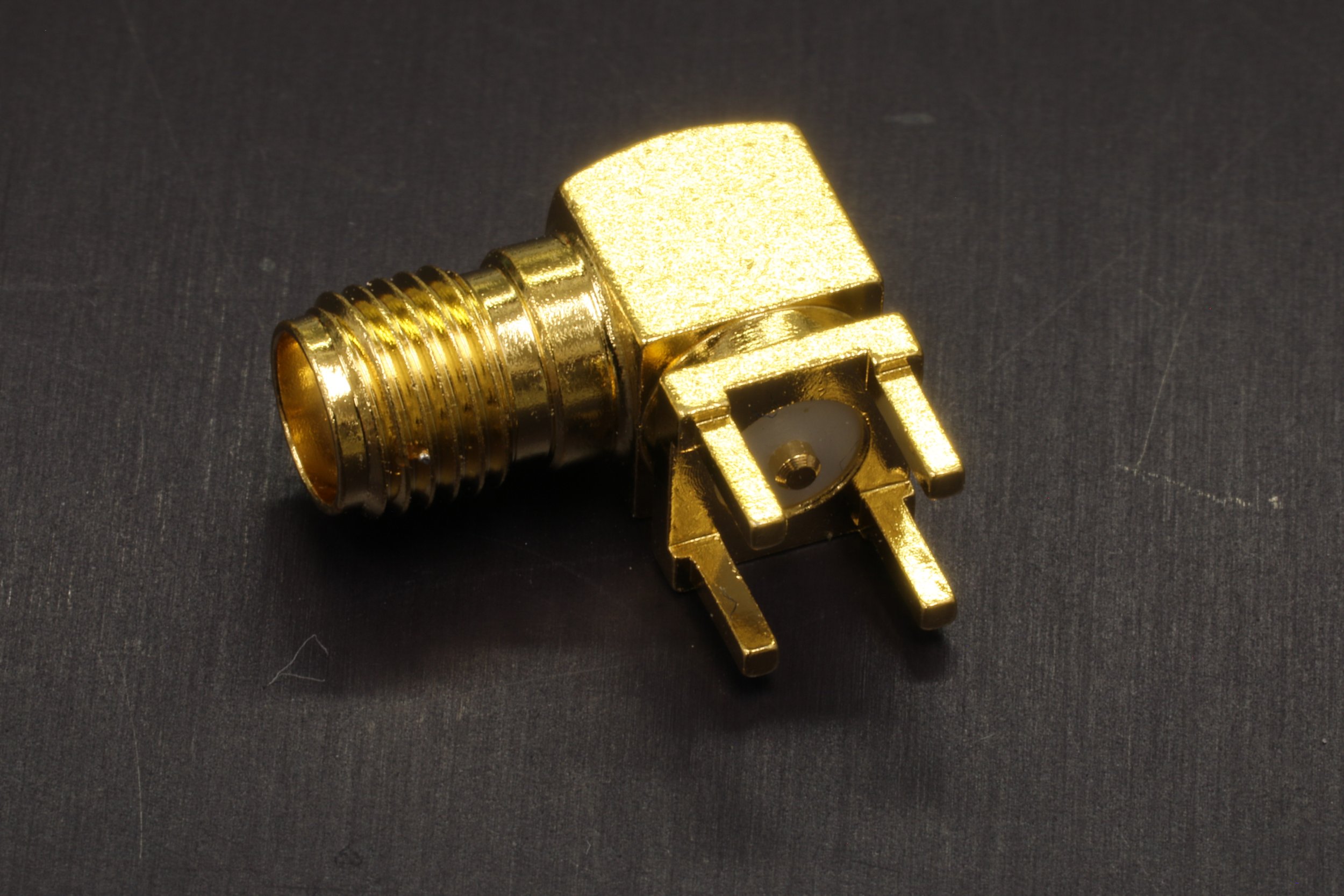

MILITARY & AEROPACE ELECTRONICS

Design and build high-frequency power amplifiers in custom ceramic packaging.

-

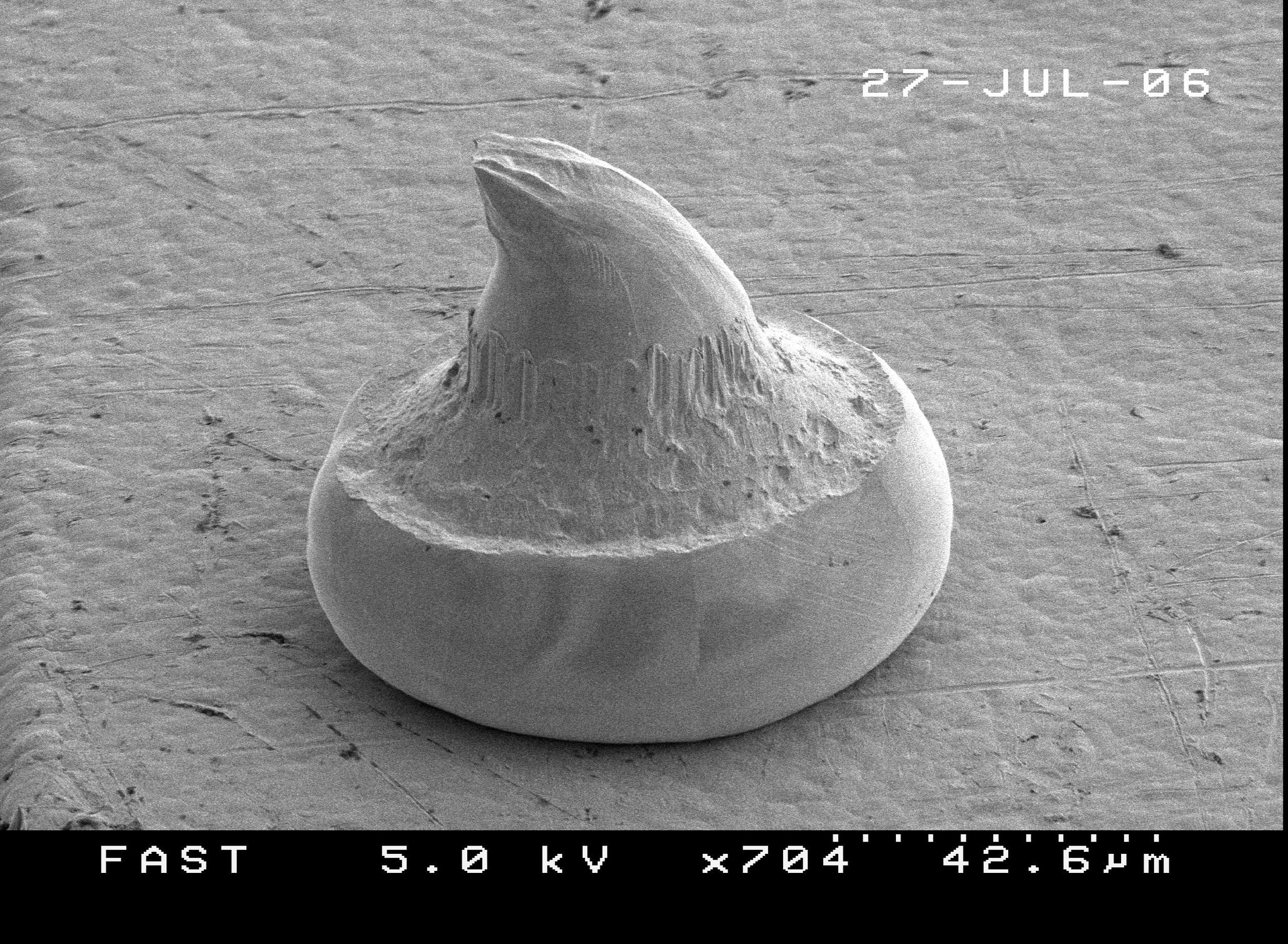

FAILURE ANALYSIS LAB

Inhouse FA Lab including X-ray, Wire Bond Pull Test, Die Sheer Test, C-SAM, CEM, and optical inspection.

-

CERAMIC SUBSTRATES

Custom fast-turn, multi-layer ceramic substrates using LTCC ceramic technology.

-

EUTECTIC DIE ATTACH

Design and manufacture graphite tooling inhouse to shorten delivery times.

-

WAFER PROCESSING

Our experienced lab technicians conduct wafer sawing, wafer wash, and pick and place.

-

WIRE BONDING

Gold Wire Bonding

Aluminum Wire Bonding

Wedge to Wedge Bonding

Automatic Bonding

RF Ribbon Bonding

-

CUSTOM GRAPHITE TOOLING

Inhouse designers and machinists fabricate custom graphite tooling and fixturing.

-

INHOUSE MACHINE SHOP

Inhouse machinists facilitate quick turn, custom tooling and semiconductor test fixtures.